- Products

- Systems

- Tools & Services

News

Atlas/Aval External Thermal Insulation Fire Safety Policy

1. Introduction

Fire safety is one of seven basic requirements related to construction objects. All building elements and building materials used in a given facility must provide adequate fire resistance, fire safety and adequate evacuation time. Thermal insulation is one of the building elements which has a very significant impact on the fire safety – how to determine the fire safety of a building using the comprehensive Atlas/Aval ETICS (External Thermal Insulation Composite System)?

2. Knowledge of building code regulations is essential

According to the regulations, buildings must be designed and constructed in such a way that in the event of fire:

- the structure load-bearing capacity is maintained for a sufficiently long period of time;

- the formation and spread of fire and smoke is limited;

- the spread of fire to adjacent buildings is limited;

- the people inside the building can safely leave the facility or be rescued;

- the safety of rescue team is taken into account.

Such stated provisions impose on the architects and constructors a number of obligations regarding, among others: selection of the type of materials used and design of detailing solutions. It is worth emphasizing that each country can have slightly different rules in this matter, so one must remember that local guidelines should always be followed. In most countries, fire safety regulations are closely related to the height of the facilities or, possibly, to the technology of their structure. Detailed information on the design solutions required for buildings of specific purpose or height is also provided in the ETICS technical specifications or certificates e.g. BBA and NSAI certificates. They include, among others, recommendations concerning the conditions of use of firestops, in the form of at least 200 mm high, continuous barrier of non-combustible material (mineral wool), on walls insulated with polystyrene.

2.1. Fire safety regulations regarding ETICS in Great Britain

I. The document corresponding to External Fire Spread in England and Wales is “The Building Regulations 2010, Approved document B (Fire Safety)”. According to paragraph 8.3 of the given document: “The external walls of the building should have the appropriate fire resistance given in Appendix A, Table A1, unless they form an unprotected area under the provisions of Section 9.” The external walls are divided into three types:

a) any part less than 1,000 mm from any point on the relevant boundary;

b) any part 1,000 mm or more from the relevant boundary;

c) any part adjacent to an external escape route.

The minimum provisions regarding resistance to fire penetration (integrity) and resistance to the transfer of excessive heat (insulation) for exterior walls depending on the type are as follows:

Table 1: Provisions for fire resistance (insulation and integrity) of external walls in England and Wales

|

Part of the external wall |

Minimum provisions when tested to the |

|

|

|

Insulation |

|

|

a) any part less than 1,000 mm from any point on the relevant boundary |

30 minutes if the height of top floor is not more than 5 metres above ground |

60 minutes if the height of top floor is more than 5 metres above ground |

|

b) any part 1,000 mm or more from the relevant boundary |

15 minutes |

|

|

c) any part adjacent to an external escape route |

no provision (with exceptions) |

|

|

|

Integrity |

|

|

a) any part less than 1,000 mm from any point on the relevant boundary |

30 minutes if the height of top floor is not more than 5 metres above ground |

60 minutes if the height of top floor is more than 5 metres above ground |

|

b) any part 1,000 mm or more from the relevant boundary |

30 minutes if the height of top floor is not more than 5 metres above ground |

60 minutes if the height of top floor is more than 5 metres above ground |

|

c) any part adjacent to an external escape route |

30 minutes |

|

Another part of the aforementioned document which directly relates to the ETICS is paragraph 8.4: “The external surfaces of walls within 1,000 mm of the relevant boundary should meet Class 0 (National Class) or Class B-s3,d2 or better (European Class) […]”

Atlas/Aval ETICS systems are classified: A2-s2, d0, B-s1, d0 or B-s2, d0 and, therefore, meet the requirement of External Fire Spread.

II. The document corresponding to External Fire Spread in Scotland is “The Building (Scotland) Regulations 2004”. In terms of spread to neighbouring buildings, the paragraph 2.6 states that: “Every building must be designed and constructed in such a way that in the event of an outbreak of fire within the building, the spread of fire to neighbouring buildings is inhibited.”

Atlas/Aval ETICS systems have “low risk” surface spread of flame classification and can satisfy this requirement.

Regarding the spread on external walls, the document says that: “Every building must be designed and constructed in such a way that in the event of an outbreak of fire within the building, or from an external source, the spread of fire on the external walls of the building is inhibited.” according to paragraph 2.7.

Atlas/Aval ETICS systems satisfy this requirement as well.

III.The document corresponding to External Fire Spread in Northern Ireland is “The Building (Northern Ireland) Regulations 2012”. Paragraph 36 relates to external fire spread: “The external walls and roof of a building shall be so designed and constructed that they afford adequate resistance to the spread of fire over them, and from one building to another, having regard to:

a) in the case of an external wall – the use, position and height of the building;

b) in the case of a roof – the use and position of the building.”

Atlas/Aval ETICS systems meet the requirement above.

2.2. Fire safety regulations regarding ETICS in Ireland

The document which relates to Fire Safety in Ireland is “Building Regulations 2006, Technical Guidance Document B, Fire Safety”. The External Fire Spread subject is included in section B4: “The external walls and roof of a building shall be so designed and

constructed that they afford adequate resistance to the spread of fire to and from neighbouring buildings.”

The Fire Spread in relation to external surfaces is mentioned in paragraph 4.1.4: “The external surfaces of walls should meet the provisions in Table 4.1. However, the total amount of combustible material may be limited in practice by the provisions for space separation in sub-section 4.2 (see par. 4.2.6).”

Table 2: Provisions for external surface of walls in Ireland

Source: Building Regulations 2006, Technical Guidance Document B, Fire Safety

Atlas/Aval ETICS systems meet the Irish requirements regarding fire safety.

2.3. Fire classification of construction products

Fire classification of construction products (including ETICS) under the European Standard is organised in accordance with BS EN 13501-1:2002 Fire classification of Construction products and building elements, Part 1 – Classification using data from reaction to fire tests. The Standard distinguishes three parameters: EuroClass (Primary Class), class of smoke development, class of burning droplets.

I. Primary Class

There are 7 primary classes determined. Materials or products are classified as A1, A2, B, C, D, E or F, where A1 is the highest class – it corresponds with building products with the best resistance to fire, on the other hand F is the lowest class – it corresponds with building products which are the most vulnerable to fire.

Table 3: Fire classification of construction products – Primary Class

|

Primary Class |

Relation to fire |

Flaring up during the RCT reference test |

Exemplary products |

|

A1 |

no contribution to fire |

no flaring up, min. amount of burning heat |

concrete, steel, glass wool |

|

A2 |

no contribution to fire |

no flaring up, low amount of burning heat |

plasterboard, high density mineral wool, |

|

B |

very limited contribution to fire |

no flaring up |

hard PVC |

|

C |

limited contribution to fire |

flaring up not earlier than after 10 minutes at 300 kW heat stream |

some PU (PIR) foams, plasterboard with paper cover |

|

D |

acceptable contribution to fire |

flaring up not earlier than after 2 minutes at 100 kW heat stream |

most PU (PIR) foams, unprotected wood |

|

E |

acceptable contribution to fire |

flaring up earlier than after 2 minutes at 100 kW heat stream |

foamed plastics of reduced combustibility, polystyrene, PU (PIR) with retardants |

|

F |

no performance requirements |

not tested or none test passed |

foamed plastics |

II. Smoke development

Table 4: Fire classification of construction products – Smoke development

|

Class of smoke development |

Reaction in the presence of fire |

|

s1 |

the structural element may emit a very limited amount of combustion gases |

|

s2 |

the structural element may emit a limited amount of combustion gases |

|

s3 |

no requirement for restricted production of combustion gases |

III. Burning droplets

Table 5: Fire classification of construction products – Burning droplets

|

Class of burning droplets |

Reaction in the presence of fire |

|

d0 |

burning droplets or particles must not be emitted from the structural element |

|

d1 |

burning droplets or particles may be released in limited quantities |

|

d2 |

no requirement for restriction of burning droplets and particles |

3. Comprehensive system is needed

Atlas/Aval ETICS technology consists in attaching to the external walls a layered system composed of insulating material (EPS or Mineral Wool boards), basecoat with reinforcing fiber glass mesh and thin-coat render. Each of these layers has a certain technical function in the system, and therefore also affects the performance and durability of ETICS as a whole – including fire safety. This situation results from the fact that the manufacturer applying for a European Technical Assessment is obliged to carry out a number of different studies and laboratory tests in which all the products intended for the complete insulation system are tested rather than individual materials. In case of fire safety, the system reaction to fire action is checked.

|

Atlas/Aval ETICS types |

Reaction to fire according |

|

Atlas/Aval ROKER ETICS with Mineral Wool boards with mineral/inorganic based rendering system |

A2 – s2, d0 |

|

Atlas/Aval ROKER ETICS with Mineral Wool boards with organic based rendering system |

B – s1, d0 |

|

Atlas/Aval ETICS with EPS boards with mineral/inorganic based rendering system |

B – s1, d0 |

|

Atlas/Aval ETICS with EPS boards with organic based rendering system |

B – s2, d0 |

Hence, there is an absolutely necessary requirement to use only complete and comprehensive ETICS. Selected ETICS must be provided by a single manufacturer and must correspond with valid technical specification.

|

Atlas/Aval ETICS has a technical specification in the form of European Technical Assessment EAT-07/0187, which covers a complete set of products for applying exterior wall insulation. The European Technical Assessment allows for the application of the system in the entire European Union. Notwithstanding this fact, Atlas/Aval ETICS has obtained a permit for use in Ireland (NSAI Certificate no. 10/0347) and in England, Wales, Scotland and Northern Ireland (BBA Certificate No 13/5018). |

4. Proper installation

Carrying out the insulation work correctly is important not only for quality, durability and visual appearance of ETICS – it is also extremely important in regard to fire safety. This applies in particular to two aspects of installation: correct bonding method between thermal insulation material and the substrate and paying attention to the proper installation in the area of windows and doors.

When the polystyrene boards are to be fixed to the substrate, it is necessary to use the “strip-point” method of adhesive bonding – it is not permitted to bond the boards using point method only. A point method of polystyrene bonding produces voids between the wall and the polystyrene – they are not filled with adhesive. The “strip-point” method consists of minimum 3 cm wide circumferential ribbon of adhesive. For the rest of the surface the mass should be spread in the form of patches of a diameter of 8 up to 12 cm. The total area of adhesive applied should cover at least 40% of the board surface. The exact amount and the thickness of the adhesive layer depends on the state of the substrate and must be selected to provide the required adhesion.

Figure 1: “Strip-point” method of adhesive application

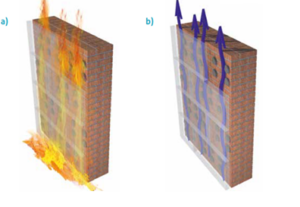

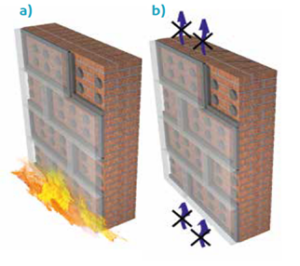

In the event of a fire in this space, there occurs a chimney draft phenomenon caused by the difference of temperature of cold air outside and hot air resulting from the polystyrene burning. Negative pressure is produced, so that the flames together with the hot fire gases are sucked into the space beneath the polystyrene boards. Moreover, the hot air in this area also contributes to faster melting of the polystyrene layer, and in the resulting additional space further combustion and faster fire spread is possible. As a result, this can contribute to extremely rapid and uncontrolled spreading of fire on an insulated wall, even between the stories. “Strip-point” method of polystyrene bonding prevents from leaving the voids under the insulation layer – each of the polystyrene boards creates the space with the encased air layer. Properly applied adhesive covers about 40% of the bottom of the insulation board, and after pressing against the substrate about 60% – it greatly improves the fire safety for the entire ETICS.

Figure 2: Point method of polystyrene bonding –

blue arrows show the potential spread of fire beneath the polystyrene boards.

Figure 3: „Strip-point” method of polystyrene bonding –

the wall is protected against spread of fire beneath the polystyrene boards.

The second aspect is related to the careful installation of ETICS in the area of windows and doors. Any execution errors on site may cause slits in the connection between render and the basecoat which allow for free fire access to the combustible insulation core of polystyrene boards.

4.1. Special measures in the Great Britain

I.Atlas/Aval ROKER ETICS with Mineral Wool boards with mineral/inorganic based rendering systemwithA2 – s2, d0 reaction to fire is considered suitable for use on or at any distance from the boundary without height restrictions.

II. Atlas/Aval ROKER ETICS with Mineral Wool boards with mineral/inorganic based rendering system with B – s1, d0 reaction to fire:

– is considered suitable for use on or at any distance from the boundary without height restrictions in England and Wales and Northern Ireland,

– is considered suitable for use for houses on or at any distance from the boundary restrictions in Scotland; for flats and maisonettes and non-domestic buildings in Scotland the system is suitable only for use more than one metre from the boundary,

– in Scotland the system is restricted for use in buildings up to 18 metres in height and calculations for unprotected areas may apply dependent on the fire resistance characteristics of the wall.

– for application to second storey walls and above, it is recommended that the designer considers at least one stainless steel mechanical fixing per square metre as advised in BRE Report BR 135 : 2013

III. Atlas/Aval ETICS with EPS boards with mineral/inorganic based rendering system with B – s1, d0 reaction to fire and Atlas/Aval ETICS with EPS boards with organic based rendering system with B – s2, d0 reaction to fire:

– are considered suitable for use on or at any distance from the boundary and are restricted for use in buildings less than 18 m in height in England and Wales and Northern Ireland

– are classified as “low risk” combustible materials and must not be used within 1 m of the boundary in Scotland. In addition they are restricted for use in buildings less than 18 m in height and calculations for unprotected areas apply with some minor exceptions.

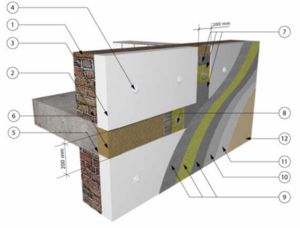

– application to second storey walls and above should include at least one stainless steel mechanical fixing per square metre and fire barriers in line with compartment walls and floors (see Figure 1). For installation of fire barriers and steel fixings refer to the guidance in BRE Report BR 135.

Figure 4: Stainless steel fixing and fire barrier in ETICS

Source: BBA Agrément Certificate 13/5018 Product Sheet 1

4.2. Special measures in Ireland

– All four Atlas/Aval ETICS systems are suitable for use up to a maximum of six stories (18 metres) in height on purpose groups 1(a), 1(b), 1(c), 2(a), 2(b), 3, 4(a) and 4 as defined in Technical Guidance Document (TGD) to Part B of the Building Regulations 1997 to 2011.

– With regard to fire stopping of cavities and limitations on use of combustible materials, walls must comply with Sections B3.2, B3.3, B3.4 and B4 of TGD to Part B of the Building Regulations 1997 to 2011.

– Stainless steel fire fixings to be provided at the rate of one per square metre above two stories. The fixing design should take account of the extra duty required under fire conditions.

– Vertical and horizontal lamella fire barriers shall be provided at each compartment floor and wall, including the second floor level of a three-storey single occupancy house. Firebreaks should be adhesively bonded to the substrate and mechanically fixed with stainless steel fire fixings at 300 mm centres.

Figure 5: Vertical and horizontal lamella fire barriers in Ireland

Source: Irish Agrément Board Certificate no. 10/0347

– The firestop should be of non-combustible material, i.e. Rockwool (slab of minimum density 120kg/m3), be at least 200 mm high, continuous and unbroken for the full perimeter of the building and for the full thickness of the insulation. Glass wool is not suitable for use as a firestop.

– Combustible material must be separated from a brick or block work chimney by at least 200 mm from a flue, or 40 mm from the outer surface of the brick or block work chimney, in accordance with Clause 2.15 of TGD to Part J of the Building Regulations 1997 to 2011. Metal fixings in contact with combustible materials should be at least 50mm from flue.

5. Summary

The fire safety of buildings insulated with ETICS is well recognized and additionally covered by building regulations including buildings maintenance. The ETICS described within technical specifications (European Technical Assessments, local technical certificates. e.g. BBA, IAB) are tested for reaction to fire during the approval and certification process – owing to that, each architect, engineer or other professional individual can select a material solution that is appropriate for the particular application.

It should also be stressed that careful installation of Atlas/Aval ETICS including proper render and basecoat application within the recommended thickness forms a protective layer for the polystyrene. It provides the insulated building with a protection against fire for sufficient time period and gives adequate fire safety to the building users.