- Products

- Systems

- Tools & Services

News

What adhesive to choose for application of floor tiles?

Contractors have been using ready-made adhesives for over 25 years. In the past, one mortar was used to bond all kinds of tiles to any type of substrate. Nowadays, we seek a specialist product which guarantees high quality and convenience of work. Atlas response to these requirements is a high-quality pourable adhesive for floor tiles – ATLAS Plus Mega.

Ready-made mortars were initially used for fixing all types of tiles to any substrate with a thin coat (up to 5 mm). They were used on floors and walls, indoors and outdoors. However, adhesives of basic or universal parameters were not always good enough to fulfill contractor’s or investor’s expectations. Therefore, some dozen years ago adhesives adapted to specific tile or substrate types (wall or floor) entered the market. The perfect example of such specialized adhesive in Atlas portfolio is Plus Mega (and Plus Mega Whitebased on white cement) – a professional adhesive for bonding floor tiles, labeled with C2ES1 symbols (according to PN-EN 12004 standard). It is an adhesive with 2 in 1 feature – it offers not only the ability of tiles bonding but also slight leveling of uneven substrate.

|

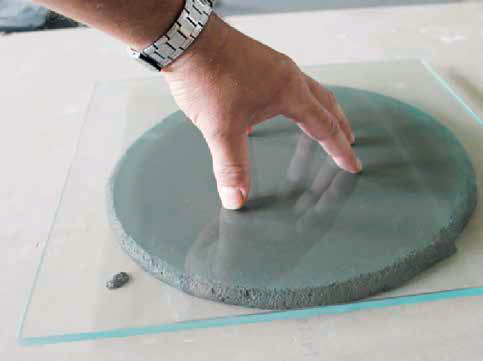

Application principles Bear in mind! Use appropriate trowel with semi-circular or diagonal notches to spread the adhesive over the substrate. This type of trowel provides 100-percent filling beneath a tile and faster adhesive distribution. When applying Plus Mega one needs to use different fixing technique: when the tile is laid on the adhesive surface it needs to be slightly pressed against the substrate and moved (vibrated) in several directions parallelly to the substrate. Then the adhesive flows easily and we have the certainty that it fills any gaps beneath the tile. When Plus Mega is in use, there is no need to apply combined bonding method consisting in application of the adhesive both upon the substrate and upon the tile. An usual method of adhesive distribution over the substrate is good enough. It facilitates and speeds up the work. It results from one of the product crucial characteristics – perfect flow ability. Only correct use of pourable adhesive guarantees 100% filling beneath a tile.

|

Cold/warm, indoors/outdoors

Adhesives for floors must first of all guarantee that the floor top finish will be resistant to load and abrasion during its entire lifespan. Most often tiles are bonded to substrates with underfloor heating or on terraces and balconies. Therefore, the floor must be resistant to varying weather conditions and substrate deformation under influence of temperature change.

In the case of indoor tiling of floors without underfloor heating, it is sufficient to distribute the adhesive with a square-notched trowel and then just press the tile against the substrate. These actions provide filling of more than 70% of space beneath a tile. One must remember that it is essential to keep 100% filling under a tile in case of underfloor heating systems and outdoor applications. In the case of heated floors, air enclosed beneath a tile becomes a natural insulator and reduces the whole system heating efficiency. It leads to higher energy consumption if one aims to keep the same temperature.

Moreover, space beneath tiles fixed outdoors, e.g. on balconies or terraces will sooner or later fill with water.

During winter, in subzero temperature, water turns into ice and enlarges volume by approximately 30%. It results in tiles loosening. On the other hand, on hot summer days, water turns into vapour expanding by 1,700 to 1,900 times. The vapour pressure also contributes to the tiles loosening. The easiest and most comfortable solution here is to use a thick-coat, pourable adhesive – this enables to fill the entire space beneath a tile.

|

Great possibilities! Atlas Plus Mega works perfectly on difficult substrates. It provides very good tiles bonding to the following substrates: those made of OSB, with underfloor heating, terrazzo, waterproofing, old ceramic cladding and strongly bonded layers of bitumen masses (after removing parquet) and adhesives (after removing PVC tiles) etc.

|

Use of Plus Mega indoors and outdoors

The characteristic which makes Plus Mega an exceptional adhesive is its ability to flow. Plus Mega is pourable due to the thixotropiceffect. Thixotropy makes it possible to change the adhesive consistency from thick to thin. It is especially noticeable when unmixed adhesive mortar is left in a bucket for a while – the consistency becomes so thick that the adhesive can be cut into slices. After it is mixed, its consistency changes from very thick to thin.

Possible application techniques

Depending on the application one can distinguish the following Plus Mega distribution techniques:

– the adhesive is poured directly from a bucket and distributed with a notched trowel (thin consistency) or

– it is applied upon the substrate with a trowel and only then spread with a notched trowel (thick consistency).

The adhesive becomes more liquid when pressed with a trowel. When the adhesive is spread and leveled on the surface, just before fixing the tiles, it becomes thicker. After laying a tile (under influence of its weight) and vibrating as we indicated before, the adhesive becomes more liquid once again. It ensures 100% filling, without air gaps beneath tiles.

|

Keep in mind!

The best choice for bonding absorbent tiles, which are vulnerable to discolouration, is using Atlas Plus Mega White adhesive.

|

Large/small tiles

Size of tiles has also significantly changed over the years. Nowadays, large tiles are definitely more popular than 10 or 15 years ago. Customers’ interest in large tiles forced the manufacturers to produce large-size tiles. The tile size often exceeds even the area of 1 m². Large-size tiles made it necessary to increase the thickness of the adhesive coat in order to bond the tiles correctly. It is due to the fact that the technology of production of tiles involves minor deviations from straight lines and tile flatness – they may reach up to 5%. This issue is regulated by EN 14411 standard. For example, if we take into account the linear dimension of a large tile of 1 m side length, the deviation (i.e. the protrusion of tile center in relation to the edges and corners) can be no more than 2 mm. This difference must be compensated by greater thickness of the adhesive coat beneath a tile. Otherwise, the tile would be bonded only locally at the corners and edges. The above conditions imposed a demand for a specialist adhesive. So, a variety of adhesives for large-size tiles appeared on the market. The characteristics which determine whether they can be used for particular type of cladding are indicated in their technical data sheets. Most importantly, permissible adhesive layer thickness is indicated there. The general rule can be stated as follows: the larger the tile is, the thicker must be the adhesive layer beneath it.

Plus Mega in use for large/small size tiles

Plus Mega is deformable according to S1 class characteristic determined by PN-EN 12004 standard. It is recommended for bonding the tiles characterised by:

– medium and large-size,

– medium and low water absorptiveness: ceramic (terracotta, stoneware, milled rock, clinker), cement, stone, etc.

Excellent adhesive consistency makes leveling very easy. Moreover, it allows for forming a small decline within the adhesive layer. Due to the adhesive plastic consistency and wide range of possible thickness, one can easily form a slope. Extended open time enables laying the tiles on the adhesive even up to 30 minutes since the adhesive spreading upon the substrate – it can be applied on a large area at one time. It speeds up the work pace. Plus Mega is a thick layer adhesive for use with 4 up to 20 mm thick layers. There is no need for applying any additional leveling mortar when Plus Mega is in use.

Even if it is applied with the maximum thickness it does not flow from beneath the tile and does not pull it down after binding. This is achieved by the use of specially selected broken aggregate. It stacks in the mixture similarly to the subcrust used in construction of roads. In addition, among the features which make Plus Mega an absolutely outstanding adhesive one may find:

– perfect filling of free spaces beneath tiles, in result complete support of tiles (including large-size ones) is provided – it eliminates the possibility of tile cracking due to impact or great load pressure at the point of insufficient tile support.

– adhesive ability to be deformed without cracking – therefore, the adhesive can eliminate the movement of any origin between the cladding and the substrate.

Table 1. Consumption of Atlas Plus adhesive for different tile size.

|

Tile size [cm] |

Recommended trowel size* [mm] |

Consumption [kg/m2] |

|

15 x 60 |

8 |

3.0 |

|

25 x 40 |

8 |

3.0 |

|

30 x 30 |

8 |

3.0 |

|

30 x 60 |

10 |

3.8 |

|

40 x 40 |

10 |

3.8 |

|

50 x 50 |

10 |

3.8 |

|

60 x 60 |

12 |

4.5 |

*Notched trowel. Trowel with semi-circular notches – consumption 6.6 kg/m2 (14 mm – notches size).

Original text: Włodzimierz Krysiak, ATLAS Group

English text: Piotr Marciniak, ATLAS Group